end suction pump meaning

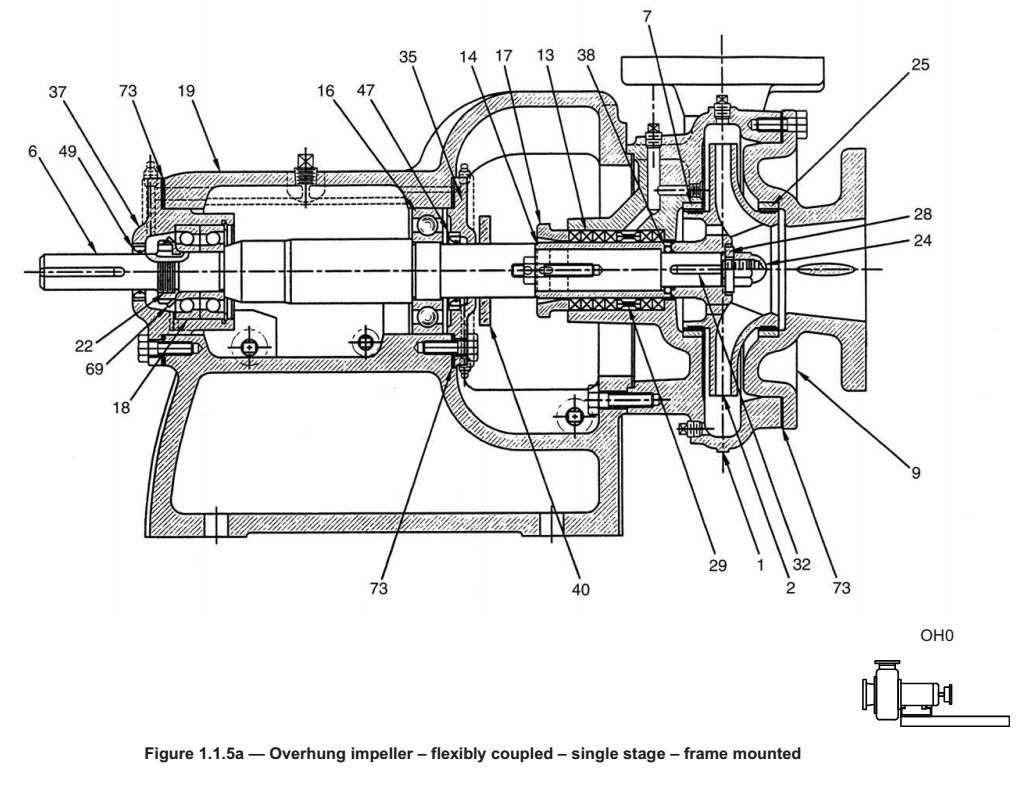

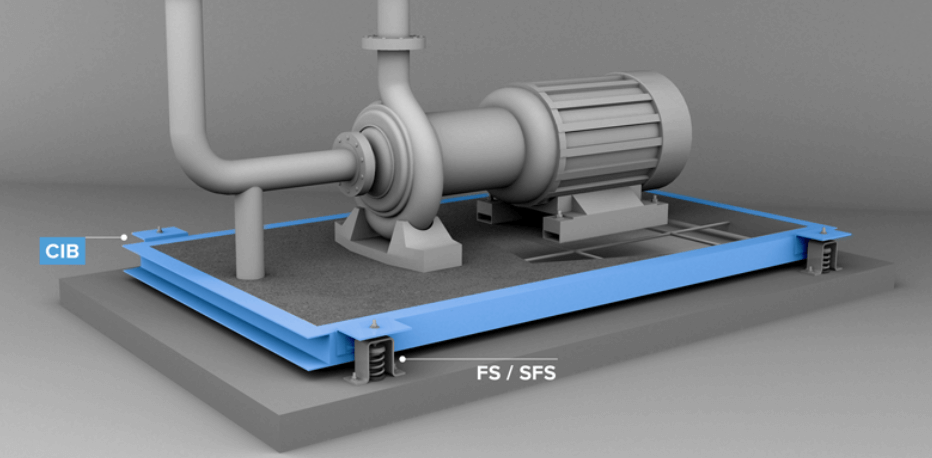

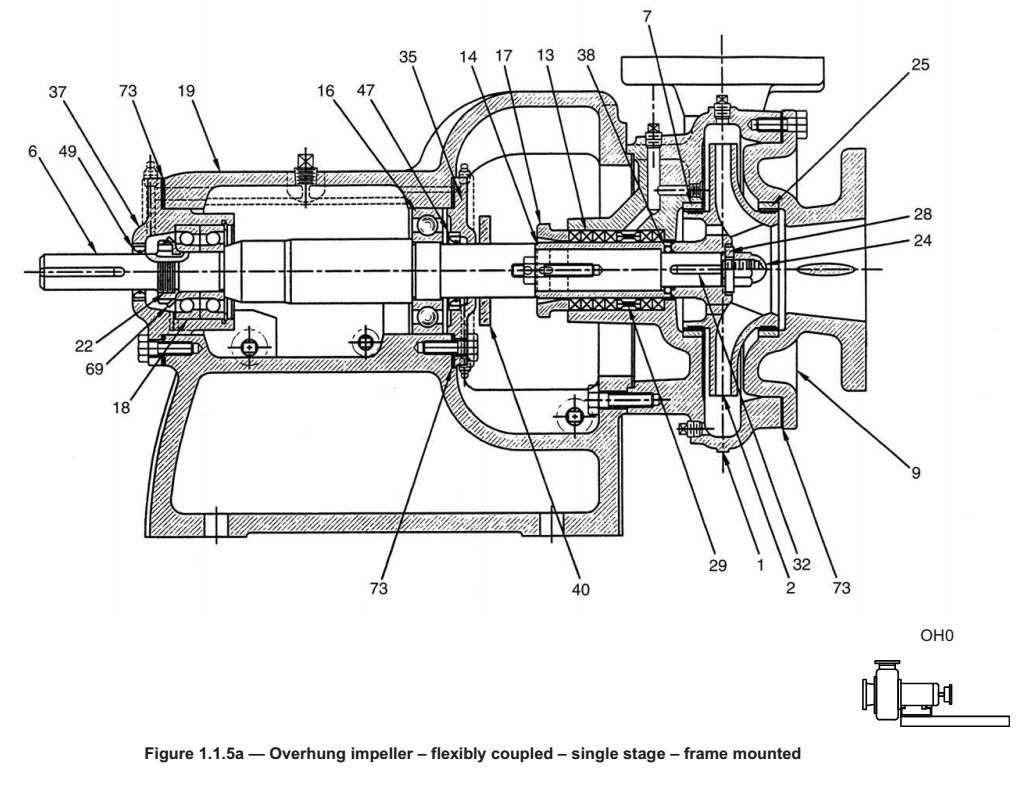

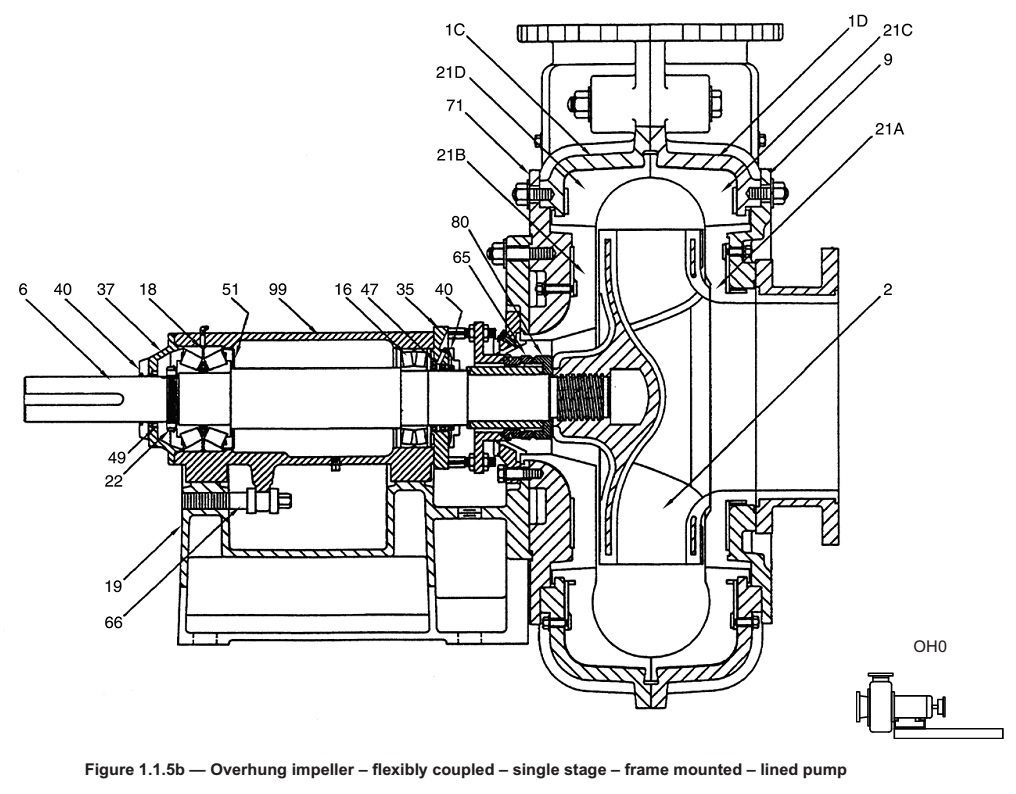

This end suction pump choice is also a candidate for water service flow rates above about 3000 to 5000 gpm even though many pump users would probably be looking at Double Suction between bearing split case pumps in this flow range. The back pull out design is a standard feature and allows easy removal of the impeller and shaft with the complete drive and bearing assembly while keeping the piping and motor in place.

End Suction Pump Vs Split Case Pump Youtube

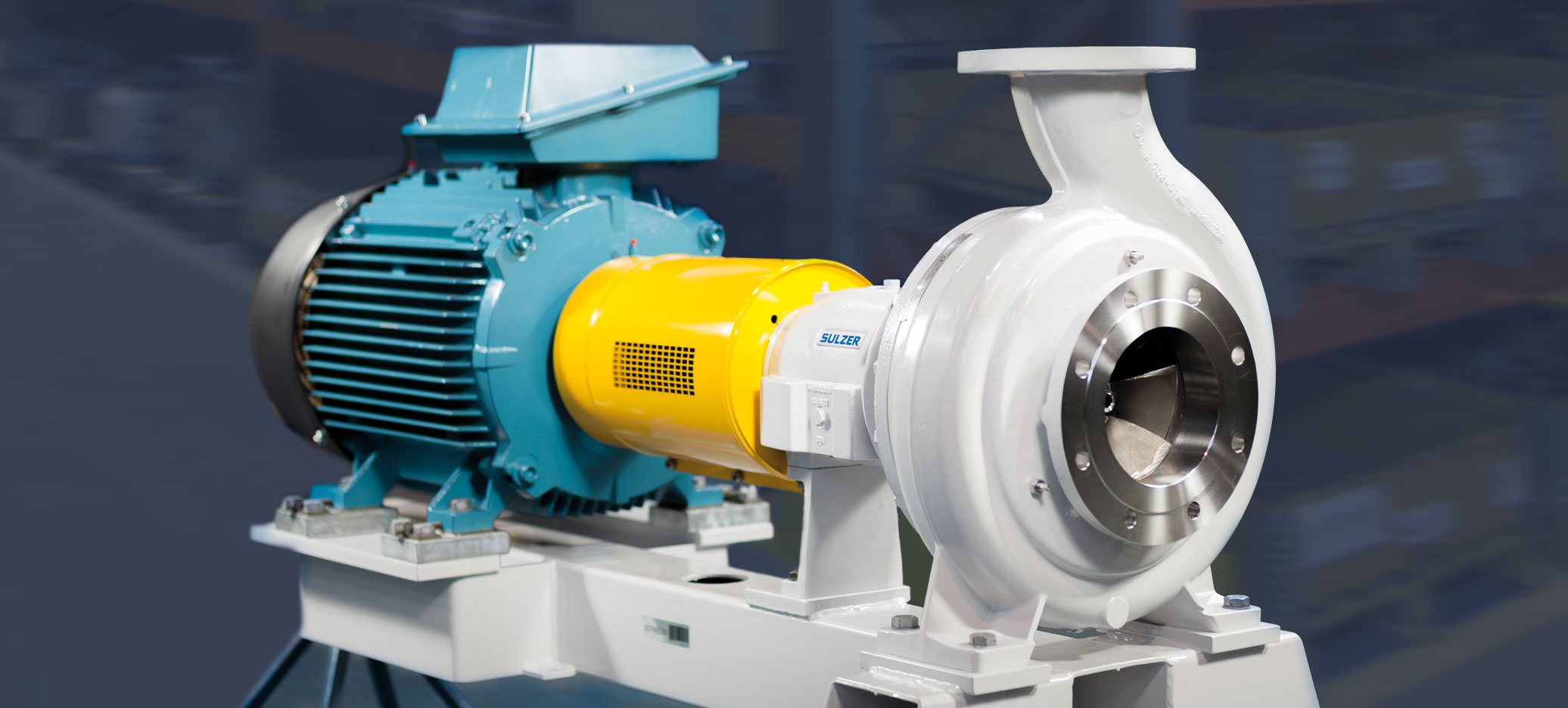

An end suction pump is the most basic type of centrifugal pump typically designed with a casing.

. Available in a wide range of sizes construction materials and designs they can be used to pump a variety of fluids from. A flooded suction pump like any other pump is used to move liquids from one point to another. An ANSI pump is an end-suction pump that conforms to the dimensional envelope described in the ANSI pump standard.

End suction pump is a kind of water pump that is widely used in agriculture. Is that the flooded suction pump is gravity fed and mounted outside of the tank or hopper which holds the slurry or fluid. A typical centrifugal pump the workhorse of industry.

LC Close Coupled LCS Split Coupled LF Frame Mounted LCV Vertically Mounted Close Coupled Grundfos PACO line of end suction single stage pumps sets the industry standard in performance quality and durability. Double suction between bearing split case pumps see figure 3. When the flow required is very high a.

The major difference between a flooded suction and submersible pumps. The suction is present on one end and the discharge is placed at the top. An ANSI pump is one that conforms to ANSI Standard B731.

Cost effective and reliable they are suitable for a range of pumping applications. End suction pumps generally have a. NPSH H1 ZD p amb - p vρ 1g where H1 inlet head Z D difference between NPSH datum plane and reference plane.

End suction pumps are one of the most common types of centrifugal pumps. Single suction means as the name signifies one-sided suction of the impeller. The pump is a centrifugal single stage single suction type.

With 32 sizes available the PACO line of pumps is the best choice with the following qualities. End suction pumps are the most common configuration for centrifugal pumps and the least expensive configuration in many cases. This manual covers the installation operation and maintenance of Patterson Pump end suction pumps.

End suction pumps are one of the most common types of centrifugal pumps. Double suction pumps are mostly used for water supply and drainage in mines cities power stations and various water conservancy projects. When properly installed and when given reasonable care and maintenance centrifugal pumps should operate satisfactorily for a long period of time.

Self priming pump has the ability to evacuate air from the suction side at startup and then it operates similar to a normal pump. Cost effective and reliable they are suitable for a range of pumping applications. The flooded suction pump is typically positioned at the bottom or underneath the tank or.

They are almost always single stage pumps meaning they have only one impeller. End suction pump is a kind of water pump that is widely used in agriculture. Net Positive Suction Head is the absolute inlet total head above the head equivalent to the vapour pressure relative to the suction eye of the pump impeller.

This pump can have higher axial thrust due to an imbalance of flow coming in only one side. In a double suction pump the bearing nearer to the pump coupling ie nearer to the driven end is the in board bearing and the bearing on the other side of the pump is the outboard bearing. A self priming pump is a specially designed end suction centrifugal pump with an external casing that always floods the inner pump or volute.

Hence the name end-suction pump is given. Double Suction Between Bearing Split Case Pumps. A type of centrifugal pump that has a casing with the suction coming in one end and the discharge coming out the top.

It has a single-suction impeller. ANSI is an acronym that stands for American National Standards Institute. This pump can have higher axial thrust due to an imbalance of flow coming in only one side.

In this pump liquid enters in the impeller through one suction pipe only. Also known as volute pump standard pump horizontal suction pump. Liquid enters through one side only.

End suction pumps are one of the most common types of centrifugal pumps. They are almost always single stage pumps that is they have only one impeller. 1314 Net positive suction head NPSH NPSH.

They are almost always single stage pumps meaning they have only one impeller.

Types Of Pumps Used In Process Industry Centrifugal Pumps The Piping Talk

The Advantage Of Double Suction Pump Exhibition Modo Pump Co Ltd

End Suction Pumps And Split Case Pumps What S The Difference

End Suction Pumps Intro To Pumps

Pre Installation Tutorial For Nm Series End Suction Centrifugal Pumps Installation Refrigeration And Air Conditioning Centrifugal Pump

Centrifugal Pump Parts Working Diagram Marinerspoint

Step Into Modern Industrial Space Buy End Suction Pumps From Ace Manufacturers In India Industrial Pumps Pumps Manufacturing

Bare Shaft Pump Head Coupling Electric Motor Supplier Psmf 50hz Suppliers And Manufacturers Factory Direct Price Purity

End Suction Pumps Intro To Pumps

Which One Is Better Split Case Or End Suction Pump Youtube

End Suction Pumps Intro To Pumps

End Suction Pump Centrifugal Durco Flowserve Chemical Process Ireland

Types Of Centrifugal Pumps Classification Working Principles Linquip

Is Single Stage Single Suction Centrifugal Pump Centrifugal Pump

Snt Long Coupled Horizontal Self Priming Centrifugal Pump North Ridge Pumps